Continuous flow platform

1、The purpose of continuous flow platform construction

Fluid chemistry unifies the reaction system and reduces the accumulation of materials and energy per unit time through process strengthening, which is an intrinsically safe technology in pharmaceutical and chemical industry. At the same time, fluid chemical shielding or greatly reduce the amplification effect, which has a good effect on the entire research and development process, and the distance from route development to commercial production is shortened. The equipment is used to amplify the expression after the development of the route, and the whole process of the reaction is shortened, and the kilogram sample can be quickly obtained. For innovative drugs, they often need to accumulate samples, and if they can be fluidized, coupled with continuous separation technology, they can quickly get kilogram samples. The homologous reaction step in a new drug molecule can quickly and efficiently reach the amplified target compound at an early stage without consuming too much time.

2、Technology platform construction

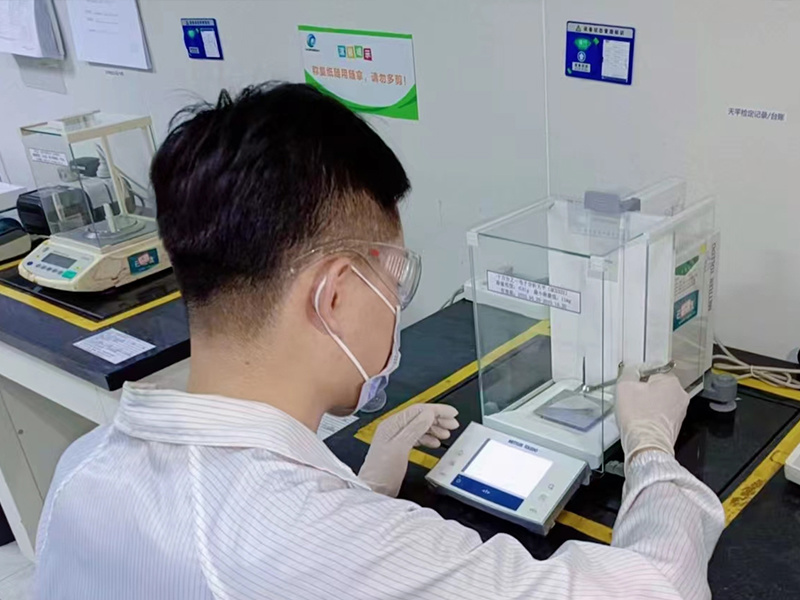

A microchannel continuous flow technology research laboratory has been built on the 3rd floor of the R&D department,and the reactor equipment is purchased from Beijing Oushisheng Company.At present,the main products are H-FLOW automatic hydrogenation reaction meter,kg integrated silicon carbide reactor,coil reactor,DP series double plunger high pressure constant flow infusion pump,double injection high pressure/low pressure constant flow infusion pump,automatic feeding calibration system,automatic back pressure valve,micro-reaction automatic liquid synthesis system and other related accessories.The basic conditions for the development of fluid chemistry process have been formed.

In addition,we have entered into a partnership with Corning Reactor Company in Changzhou,Jiangsu Province,to provide Advanced-Flow®G1 hybrid reactor and supporting equipment and researchers with technical guidance training for the fluid chemistry platform.Wuhan Zhongyou Company has purchased 5 sets of Corning glass microchannel reactors and related feed pumps,control systems and temperature controllers,and leased 5 sets of silicon carbide microchannel reactors,which have been fully used in the development and research of continuous flow technology.

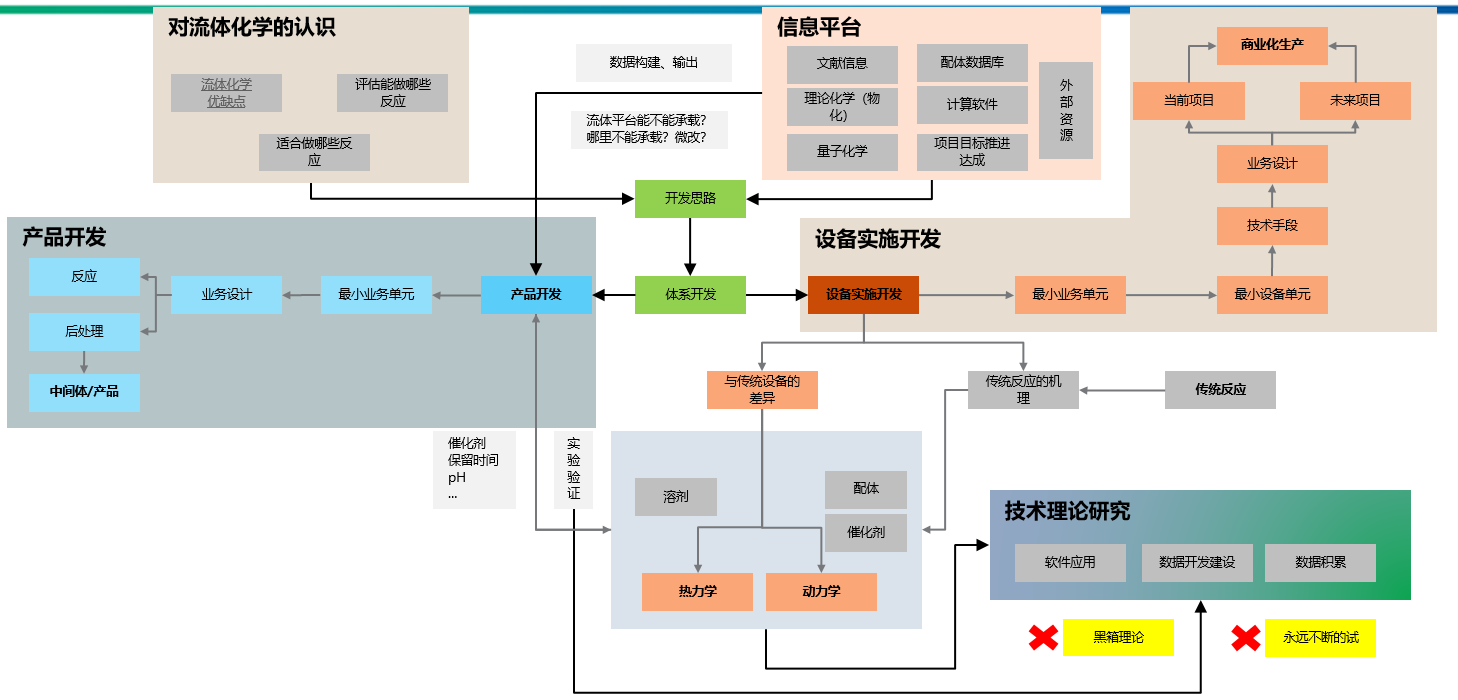

3、Research and development ideas

4、Project

Use the existing equipment of Beijing OSesheng Company to conduct research on related projects(hydrogenation reaction,bromination reaction,etc.);Self-assembly of a series of coil reactors of various specifications for the exploration of other types of reactions or other projects and feasibility analysis studies(oxidation reactions);Take advantage of Corning's G1 reactor to quickly and efficiently advance continuous flow technology development and production for related projects;Further complement continuous flow technology equipment(other special reactors,feed pumps,etc.)as well as online testing systems(online nuclear magnetic,online infrared,online ultraviolet,etc.),continuous post-processing systems(quenching,extraction,separation,centrifugation,drying,concentration,etc.)and separation and purification systems(crystallization,column separation,recrystallization,etc.).

On the other hand,expand the research team of the fluid chemistry platform,recruit or independently train scientific research talents with continuous flow technology research and development ability,clarify responsibilities and reasonable division of labor,so that the platform can run efficiently and smoothly,and truly become a technology research and development base(the company is recruiting relevant technical personnel).The organizational structure and operation mode of the fluid chemistry platform can be further clarified,and the R&D projects can be jointly determined by each person responsible for their own needs.It is suggested to take the point with the surface,steadily promote,reasonable overall planning.Take the company's project as the research basis(reaction),drive the relevant scientific research topics to explore in depth(mechanism),find the essence of the problem(key points),and fundamentally solve the difficulties(benefits).

Based on the current challenges in the R&D and production of apis,the continuous flow technology platform actively promotes the rapid development of the company's API production in line with the safe and sustainable research concept,and pays attention to diversified expansion(sorting out and establishing databases,etc.)while improving the R&D capacity,for comprehensive and comprehensive development.

R&D Style